Hari dan Yuniar (2002), “Aplikasi Aletode GERT dalam Proses Produksi”. Perencanaan dan Pengendalian Proyek Konstruksi. European Journal of Purchasing & Supply Management, 17(4), 276-286 Supply chain collaboration: Making sense of the strategy continuum. “Management Information Systems: Managing the Digital Firm, 10th edition”.

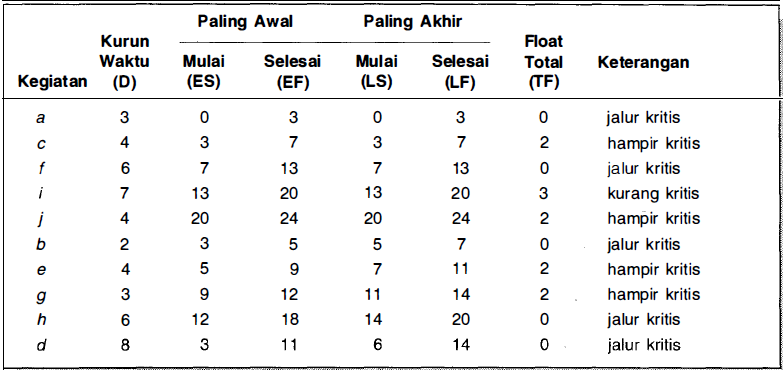

2008, “Manajemen Proyek”, Yogyakarta: Cv. produces a normal time of 74 minutes, while for an accelerated time it can be 69 minutes by doing the compressing stage. Activity J is the installation of chairs onto black powder coating iron. Activity G installation of seats, backrests, and armrests using hinge gears. Activity F installation of plastic shells for seat, backrest and arms. Activity E is cutting Oscar's velvet fabric which consists of a seat, backrest, and armrests. Activity D is foam cutting which consists of a seat, back, and armrests. Activity C is making patterns on oscar velvet which consists of seats, backs, and armrests. Activity B is making a foam pattern consisting of a seat, back, and armrests. The results of the CPM method for accelerating project time explain that activity A is preparation for preparing tools and materials. The results of the study using the CPM method produced a budget of IDR 2,580,000 million for normal costs using normal time, while for costs that were accelerated by carrying out the analysis phase to speed up project time, it was IDR 2,890,000 million. CPM (Critical Path Method) is an analytical technique for planning, scheduling and project control using the critical path method with a single estimate for the duration of an activity. Adding RFID (Radio Frequency Identification), so you don't know the cost budget and time to accelerate project completion using the CPM method to solve problems.

This study discusses one of the cinemas in the city of Depok, West Java where the object of research is cinema seats.

0 kommentar(er)

0 kommentar(er)